Welding as a Career: Complete Guide to Opportunities and Growth

Understand welding as a professional career path

Welding represent one of the about stable and rewarding career paths in skilled trades. This profession combine technical expertise with hands on craftsmanship, offer opportunities across multiple industries. Welders join materials unitedly use heat, create everything from skyscrapers to spacecraft components.

Source: nhrec.org

The weld profession attract individuals who enjoy work with their hands while solve complex technical challenges. Modern welding require precision, attention to detail, and continuous learning as technology advance. Professional welders develop specialized skills that remain in high demand across various sectors.

Career opportunities in welding

Welding careers span numerous industries, each offer unique challenges and rewards. Construction welders work on buildings, bridges, and infrastructure projects. Manufacture welders create products range from automobiles to household appliances. Pipeline welders travel extensively, work on oil and gas transmission systems.

Underwater welders combine diving skills with welding expertise, earn premium wages for specialized work. Aerospace welders work with exotic materials, create components for aircraft and spacecraft. Artistic welders create sculptures and decorative metalwork, blend creativity with technical skill.

Many welders finally transition into supervisory roles, becoming weld inspectors, supervisors, or shop foremen. Some establish their own welding businesses, provide services to local industries or specialize in custom fabrication work.

Educational requirements and training paths

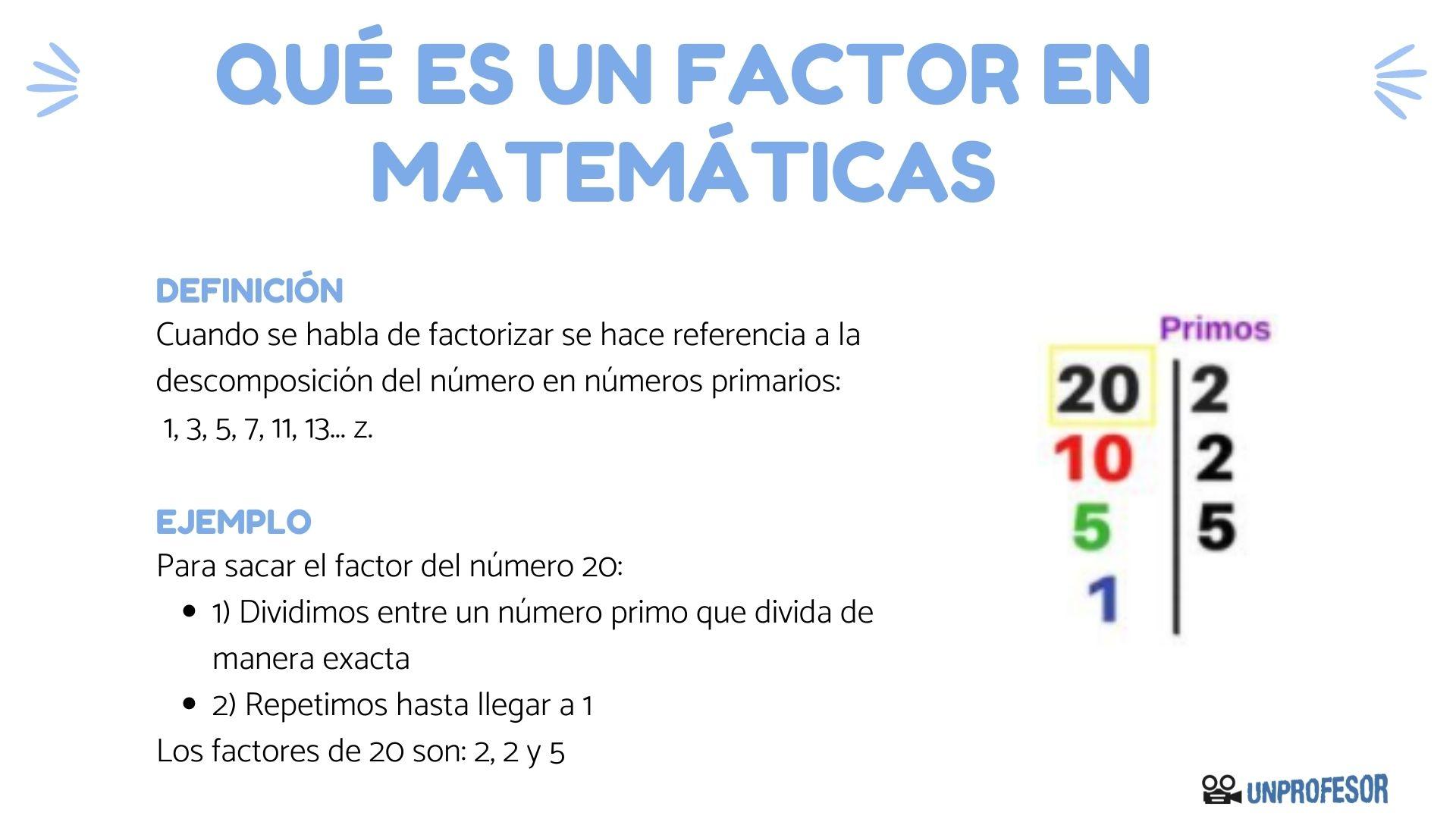

Most weld careers begin with formal training at vocational schools, community colleges, or trade programs. These programs typically last six months to two years, cover fundamental welding processes, safety procedures, and blueprint reading. Students learn various welding techniques include stick welding, MIG welding, TIG welding, and flux core welding.

Apprenticeship programs combine classroom instruction with pay on the job training. These programs, oft sponsor by unions or employers, provide comprehensive training while earn wages. Apprenticeships typically last three to four years, gradually increase responsibilities and pay rates.

Many employers provide additional training for specific welding processes or industry requirements. Continue education remain important as weld technology evolves and new materials enter the market.

Source: en.wikipedia.org

Certifications and professional development

Weld certifications validate skills and open doors to better opportunities. The American welding society (aAWS)offer numerous certification programs for different welding processes and positions. These certifications demonstrate competency to employers and oftentimes result in higher wages.

Specialized certifications include structural welding, pipe welding, and pressure vessel welding. Each certification require pass write tests and demonstrate practical welding skills under supervised conditions. Maintain certifications require periodic renewal and continue education.

Advanced certifications like certified welding inspector (cCGI)or certified welding educator ( (eCWE)en pathways to leadership roles and higher earnings. These positions require extensive experience and additional training but offer significant career advancement opportunities.

Salary expectations and earn potential

Welding salaries vary importantly base on location, industry, experience, and specialization. Entry level welders typically earn competitive wages compare to other trades, with opportunities for rapid advancement. Experienced welders in specialized fields command premium salaries.

Geographic location intemperately influence weld wages. Areas with high construction activity, manufacturing centers, or energy production typically offer higher compensation. Remote locations or hazardous work environments oftentimes provide additional pay premiums.

Specialized welding positions offer exceptional earn potential. Underwater welders, pipeline welders, and aerospace welders oftentimes earn considerably more than general welders. Overtime opportunities are common in many welding positions, interchange increase earn potential.

Self employ welders can build profitable businesses by develop specialized skills and build strong customer relationships. Mobile welding services, custom fabrication, and repair work provide entrepreneurial opportunities for experienced welders.

Work environment and conditions

Welding work environments vary dramatically depend on the industry and specific role. Shop welders work in control environments with proper ventilation and lighting. Construction welders work outside in various weather conditions and at different heights. Industrial welders may work in manufacturing facilities with shift schedules.

Safety remain paramount in welding careers. Welders must understand and follow strict safety protocols to prevent injuries from heat, fumes, and electrical hazards. Proper personal protective equipment is essential, include weld helmets, protective clothing, and respiratory protection when needed.

Physical demands include stand for extended periods, work in various positions, and lift materials. Good hand eye coordination and steady hands are essential for quality welding. Some positions require climbing, crawling, or work in confine spaces.

Industry demand and job security

Welding careers offer excellent job security due to consistent demand across multiple industries. Infrastructure maintenance and replacement create ongoing opportunities for skilled welders. Manufacture growth, especially in automotive and aerospace sectors, drive demand for qualified welders.

Energy sector expansion, include renewable energy projects, create new welding opportunities. Wind turbine installation and maintenance require specialized welding skills. Oil and gas pipeline projects provide lucrative opportunities for experienced pipeline welders.

The age workforce in skilled trades create additional opportunities as experienced welders retire. This demographic shift results in increase demand for new welders and advancement opportunities for exist professionals.

Technology and future outlook

Welding technology continue to evolve with automation and advanced materials. While some basic welding tasks may become automate, skilled welders remain essential for complex work require human judgment and adaptability. Understand new technologies become progressively important for career advancement.

Robotic welding systems require skilled operators and programmers, create new career paths for tech-savvy welders. Computer control welding equipment demand understanding of digital systems and programming concepts.

Advanced materials in aerospace, automotive, and energy sectors require specialized welding knowledge. Welders who master these new materials and processes position themselves for premium opportunities and higher compensation.

Skills for success in welding careers

Technical skills form the foundation of successful welding careers. Master various welding processes, understand metallurgy, and read blueprints are essential competencies. Quality control and inspection skills help ensure work meet specifications and safety standards.

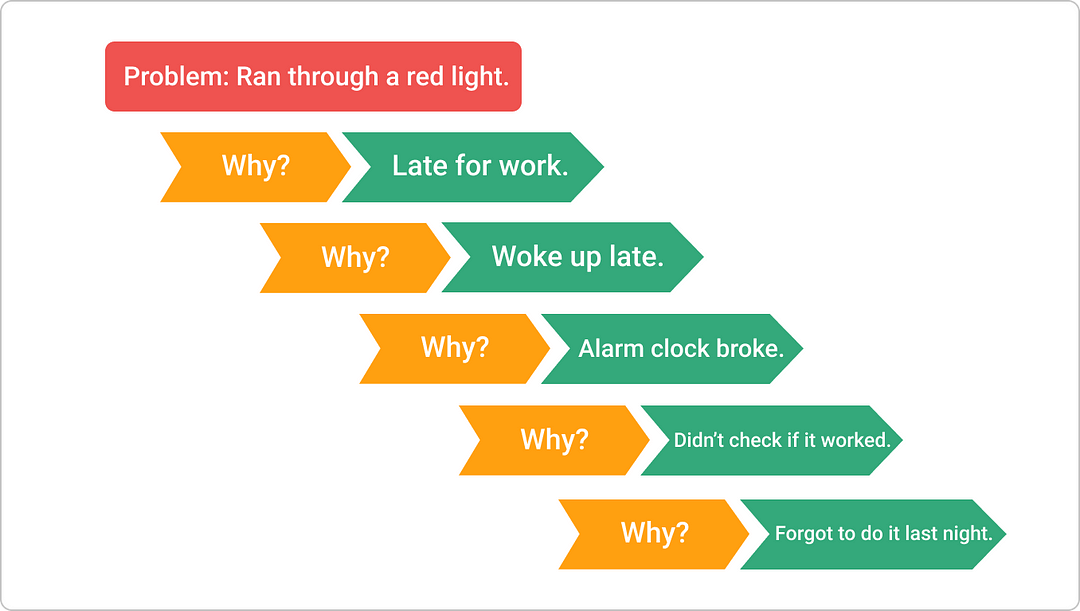

Problem solve abilities distinguish good welders from great ones. Complex projects oftentimes require creative solutions and adaptation to unexpected challenges. Mathematical skills help with measurements, calculations, and material requirements.

Communication skills become progressively important as welders advance in their careers. Supervisory roles require effective communication with team members, management, and clients. Customer service skills benefit self employ welders build their businesses.

Getting start in welding

Begin a welding career start with research training options and industry opportunities in your area. Visit local welding schools, community colleges, and trade programs to understand available options. Speak with work welders about their experiences and career advice.

Consider which weld specialization interests you nigh. Research salary expectations, working conditions, and advancement opportunities in different welding fields. Some specializations require additional training or physical capabilities.

Financial aid options may be available for weld education, include grants, scholarships, and student loans. Some employers offer tuition reimbursement for employees pursue weld certifications or additional training.

Build a strong foundation in basic welding skills open doors to specialized training and better opportunities. Focus on develop quality workmanship and safety habits from the beginning of your welding career.

MORE FROM ittutoria.net