Maintenance Protocols for Technology and Supplies: Essential Practices for Operational Excellence

Why maintenance protocols for technology and supplies matter

Maintenance protocols represent systematic approaches to preserve the functionality, reliability, and longevity of technological assets and supplies. These structured procedures serve as the backbone of operational continuity in organizations range from healthcare facilities to manufacture plants and corporate environments. Without proper maintenance systems, yet the virtually advanced technology deteriorate untimely, and critical supplies become deplete or compromise.

Organizations that implement robust maintenance protocols typically experience 30 40 % fewer unexpected equipment failures and considerably reduce downtime. This translates direct to improve productivity, cost savings, and enhance service delivery capabilities.

Key benefits of implement maintenance protocols

Extended asset lifespan

Regular maintenance dramatically extends the useful life of technology and equipment. Consider computer systems — those receive schedule maintenance, include software updates, disk cleanup, and physical cleaning, typically function efficaciously for 5 7 years. In contrast, neglect systems oftentimes require replacement within 2 3 years.

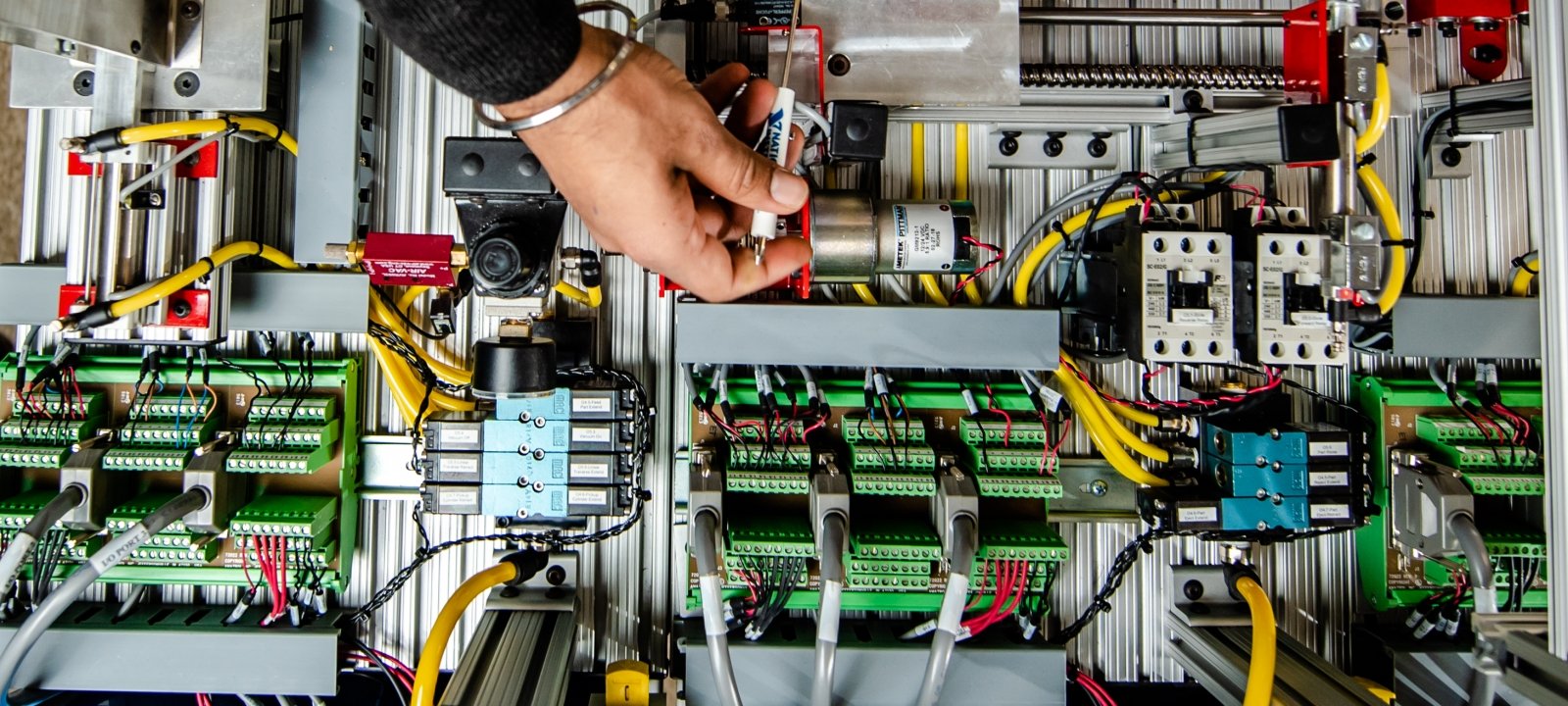

Maintenance protocols ensure that small issues get address before they develop into major problems. Something arsenic simple as dust removal from server fans can prevent overheat that might differently cause permanent damage to critical components.

Source: blog.spacerobotsclub.com

Minimized operational disruptions

Unplanned downtime create cascade negative effects throughout an organization. When critical systems fail circumstantially, productivity halts, deadlines get miss, and customer satisfaction plummets. Maintenance protocols transform unpredictable breakdowns into plan maintenance activities.

Schedule maintenance allow organizations to:

- Plan around critical operational periods

- Arrange for temporary backup systems when need

- Notify stakeholders in advance of potential service interruptions

- Allocate appropriate technical resources without emergency premiums

Cost efficiency and budget management

The financial impact of proper maintenance protocols extend far beyond the obvious repair cost savings. Organizations with mature maintenance systems typically allocate resources more expeditiously and avoid the premium costs associate with emergency repairs.

Consider these financial advantages:

- Plan maintenance typically cost 3 5 times less than emergency repairs

- Extended equipment lifecycles delay capital expenditures on replacements

- Consistent maintenance allow for more accurate budget forecasting

- Reduced energy consumption from decent maintain equipment

A manufacturing facility that implement a comprehensive maintenance protocol for its production equipment report a 28 % reduction in overall maintenance costs within the first year, while simultaneously increase equipment availability by 14 %.

Enhanced safety and compliance

Decent maintain technology and equipment operate within their design parameters, importantly reduce safety risks to users and operators. This aspect become specially critical in industries where equipment failure can lead to serious injuries or environmental hazards.

Maintenance protocols besides play a vital role in regulatory compliance. Many industries face strict requirements regard equipment inspection and maintenance:

- Healthcare facilities must maintain medical equipment accord to manufacturer specifications and regulatory standards

- Transportation companies need document maintenance records for vehicles and safety systems

- Manufacture plants require regular inspection of safety equipment and machinery

- Data centers must ensure backup systems remain functional to meet data protection requirements

Organizations that neglect maintenance not lonesome risk operational failures but besides potential regulatory penalties, legal liability, and reputational damage.

Essential components of effective maintenance protocols

Comprehensive asset inventory

The foundation of any maintenance protocol begin with a complete inventory of all technology assets and supplies. This inventory should include:

- Detailed equipment specifications and model information

- Serial numbers and identification codes

- Purchase dates and warranty information

- Location and department assignment

- Criticality rating for prioritization

- Maintenance history and requirements

Modern inventory management systems use barcode or RFID technology to track assets mechanically, provide real time visibility into equipment status and location. This technological approach eliminate the inaccuracies of manual tracking and enable more responsive maintenance planning.

Schedule maintenance calendars

Effective maintenance protocols rely on intelligibly define schedules that balance manufacturer recommendations with operational realities. These schedules typically incorporate multiple types of maintenance:

-

Preventive maintenance

regular, schedule activities design to prevent failures -

Predictive maintenance

condition base activities trigger by monitor systems -

Corrective maintenance

address identify issues before they cause failure -

Emergency maintenance

procedures for handle unexpected failures

Organizations should develop maintenance calendars that minimize disruption to core operations while ensure adequate coverage for all critical systems. Many find success with a there approach that schedule different maintenance activities accord to their impact and resource requirements.

Standardized procedures and documentation

Consistency in maintenance activities ensure quality outcomes disregarding of who perform the work. Standardized procedures should include:

- Step-by-step instructions for common maintenance tasks

- Safety protocols and require protective equipment

- Tools and resources need for each procedure

- Expect time requirements and skill levels

- Quality assurance checkpoints

- Documentation requirements

Comprehensive documentation serve multiple purposes beyond regulatory compliance. It creates institutional knowledge that remain evening when experienced staff depart, enable analysis of recur issues, and provide evidence of due diligence in maintain critical systems.

Supply chain integration

Maintenance protocols must account for the availability of necessary parts, materials, and supplies. This requires tight integration with inventory management and procurement systems to ensure:

- Critical spare parts remain in stock at appropriate levels

- Consumable supplies get reorder mechanically before depletion

- Specialized materials arrive in time for scheduled maintenance

- Vendor relationships support emergency procurement when need

Organizations with mature maintenance systems typically establish minimum stock levels for critical components base on usage patterns, lead times, and the criticality of the associate equipment.

Technology enhance maintenance protocols

Computerized maintenance management systems (cCMOS)

Modern maintenance protocols leverage specialized software to automate scheduling, tracking, and report. These systems provide significant advantages:

- Automatic generation of work orders base on schedules or triggers

- Real time tracking of maintenance activities and completion status

- Historical data analysis to identify patterns and optimize schedules

- Resource allocation and technician assignment

- Parts inventory management and automatic reordering

- Compliance documentation and report

Organizations implement CMOS solutions typically report 10 30 % improvements in maintenance efficiency and significant reductions in administrative overhead.

Internet of things (iIOT)and predictive maintenance

The integration of IOT sensors with maintenance protocols create opportunities for sincerely predictive approaches. Smart sensors can monitor:

- Equipment vibration patterns indicate potential mechanical issues

- Temperature fluctuations suggest cool problems

- Power consumption anomalies point to efficiency losses

- Usage patterns that inform optimal maintenance timing

- Environmental conditions affect equipment performance

These systems analyze patterns to predict failures before they occur, allow maintenance to be performed exactly when need kinda than on arbitrary schedules. A manufacture plant implemenIOTot base predictive maintenance report reduce unplanned downtime by 78 % while simultaneously decrease maintenance costs by 12 %.

Mobile technologies for field maintenance

Maintenance technicians progressively use mobile devices to access procedures, record activities, and communicate with support teams. These technologies enable:

- Real time access to equipment documentation and maintenance history

- Photo and video documentation of issues and repairs

- Barcode scan for quick equipment identification

- Digital checklists ensure complete procedure execution

- Immediate reporting of complete work

Organizations report significant efficiency gains when technicians can access information and report results without return to central offices or workstations.

Implementation challenges and solutions

Overcome resistance to change

Implement new maintenance protocols frequently face resistance from staff accustom to reactive approaches. Successful organizations address this challenge through:

- Clear communication about the benefits and reasoning behind new protocols

- Involvement of maintenance staff in protocol development

- Phased implementation that demonstrate early wins

- Recognition and rewards for protocol adherence

- Continuous feedback mechanisms to refine processes

Training play a critical role in overcome resistance. When staff understand not exactly how to follow protocols but why they matter, compliance increase dramatically.

Resource allocation and prioritization

Organizations seldom have unlimited resources for maintenance activities. Effective protocols must include prioritization frameworks that consider:

- Criticality of equipment to core operations

- Safety implications of potential failures

- Regulatory requirements and compliance deadlines

- Cost benefit analysis of preventive vs. Reactive approaches

- Available technical expertise and specialized tools

Many organizations adopt a risk base approach that allocate the most resources to maintain systems where failure would have the greatest negative impact.

Measure maintenance protocol effectiveness

Continuous improvement require meaningful metrics to evaluate performance. Key performance indicators for maintenance protocols typically include:

- Mean time between failures (mMTBF)for critical equipment

- Percentage of maintenance activities complete on schedule

- Ratio of preventive to reactive maintenance

- Equipment availability and uptime statistics

- Maintenance cost as a percentage of replacement value

- Energy efficiency improvements from maintain equipment

Regular review of these metrics allow organizations to refine protocols, adjust resource allocation, and demonstrate the value of maintenance investments to leadership.

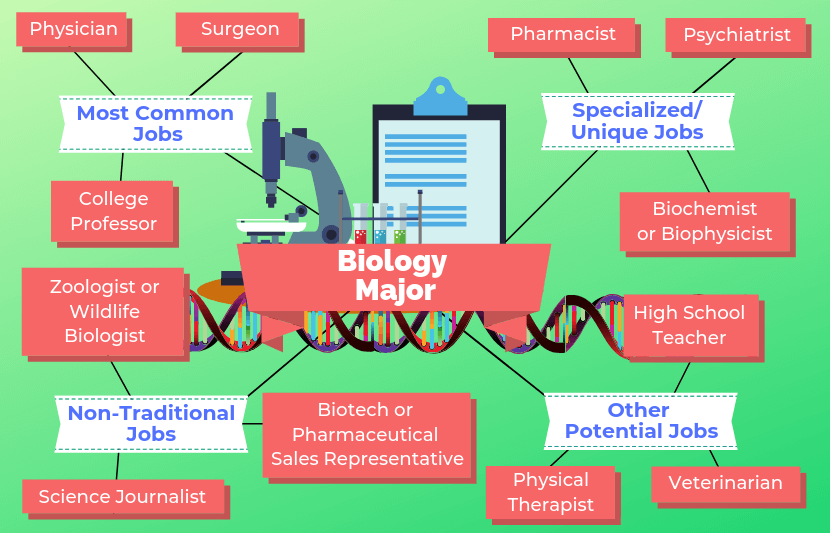

Industry specific maintenance considerations

Healthcare technology maintenance

Medical facilities face unique challenges in maintain both critical care equipment and everyday operational technology. Effective protocols must address:

- Strict regulatory requirements for medical device maintenance

- Infection control procedures during maintenance activities

- Minimal disruption to patient care areas

- Calibration and accuracy verification for diagnostic equipment

- Documentation standards for potential legal and regulatory review

Healthcare organizations typically implement multi tiered protocols that distinguish between life critical systems require redundancy and rigorous testing and administrative systems with more standard maintenance approaches.

Manufacturing and production equipment

Production environments balance maintenance needs against production schedules and output targets. Effective protocols in these settings frequently include:

- Operator level daily maintenance integrate into standard work procedures

- Condition monitor systems that detect early warning signs of failure

- Maintenance windows schedule during plan production downtime

- Critical spare parts maintain on site for rapid repairs

- Vendor service agreements for specialized equipment

Many manufacture facilities adopt total productive maintenance (tTPM)approaches that involve production staff in basic maintenance activities, create share responsibility for equipment reliability.

Information technology infrastructure

Its systems require specialized maintenance protocols that address both hardware and software components:

- Regular security patching and software updates

- Backup system testing and verification

- Network infrastructure preventive maintenance

- Data center environmental monitoring and control

- End user device refresh cycles and updates

Organizations progressively adopt automate monitoring and maintenance tools that can perform many routine tasks without human intervention, allow it staff to focus on more complex issues and strategic improvements.

Future trends in maintenance protocols

Artificial intelligence and machine learning

The next generation of maintenance protocols will leverage AI to will analyze vast amounts of operational data and will identify patterns humans might will miss. These systems promise to:

- Predict failures with greater accuracy by analyze multiple variables simultaneously

- Optimize maintenance scheduling base on operational patterns and requirements

- Identify root causes of recur issues through pattern recognition

- Recommend specific maintenance actions base on equipment history and symptoms

- Endlessly improve predictions through machine learning

Early adopters report significant improvements in maintenance efficiency and further reductions in unexpected failures compare to traditional predictive maintenance approaches.

Augmented reality for maintenance guidance

Ar technologies are transformed how maintenance procedures geto performrm, peculiarly for complex equipment:

Source: slideshare.net

- Step-by-step visual guidance overlay direct on equipment

- Remote expert assistance for field technicians

- Visual confirmation of proper component identification

- Interactive training for maintenance procedures

- Digital capture of complete work for documentation

These technologies enable less experienced technicians to perform complex procedures right, expand the available workforce for maintenance activities.

Sustainability in maintenance practices

Environmental considerations progressively influence maintenance protocols, with organizations focus on:

- Energy efficiency optimization through proper maintenance

- Waste reduction in maintenance activities

- Environmentally friendly cleaning and lubricate products

- Refurbishment and reuse preferably than replacement when possible

- Proper disposal and recycling of replace components

Organizations find that environmentally conscious maintenance practices oftentimes align with cost save objectives, create win-win opportunities.

Conclusion: the strategic value of maintenance protocols

Maintenance protocols represent far more than operational checklists — they embody strategic approaches to asset management that now impact organizational performance. By extend equipment lifespan, prevent unexpected downtime, ensure regulatory compliance, and optimize resource allocation, advantageously design maintenance protocols deliver measurable return on investment.

Organizations that treat maintenance as a strategic function kinda than a necessary expense gain competitive advantages through improved reliability, reduced costs, and enhance operational capabilities. As technology will continue to will evolve, maintenance protocols will incorporate progressively sophisticated tools for prediction, analysis, and execution, far will amplify these benefits.

The virtually successful organizations recognize that maintenance protocols are not static documents but evolve systems that require continuous refinement base on operational experience, technological advances, and change business requirements. This dynamic approach ensure that maintenance activities remain aligned with organizational goals and deliver maximum value.

MORE FROM ittutoria.net